High Gloss Waterproof Laminate Flooring

In comparison to other types of flooring, high gloss waterproof laminate floors provide a straightforward installation process due to their interlocking boards that are easy to manage. The ability to float the laminate over existing floors significantly reduces installation time compared to other materials that may require adhesives, staples, or nails. This ease of installation renders high gloss waterproof laminate flooring a DIY-friendly project suitable for individuals across all skill levels who wish to enhance their living spaces.

High Gloss Waterproof Laminate Flooring: Luxury Shine with Lasting Protection

High gloss waterproof laminate flooring offers the perfect combination of sleek style, superior moisture resistance, and long-lasting durability. Designed to elevate any space with a polished finish, high gloss waterproof laminate flooring is ideal for homeowners, designers, and property developers seeking a high-end look without sacrificing practicality.

Whether you’re upgrading a modern apartment or finishing a commercial space, high gloss waterproof laminate flooring delivers elegant aesthetics, excellent performance, and easy maintenance.

What is High Gloss Waterproof Laminate Flooring?

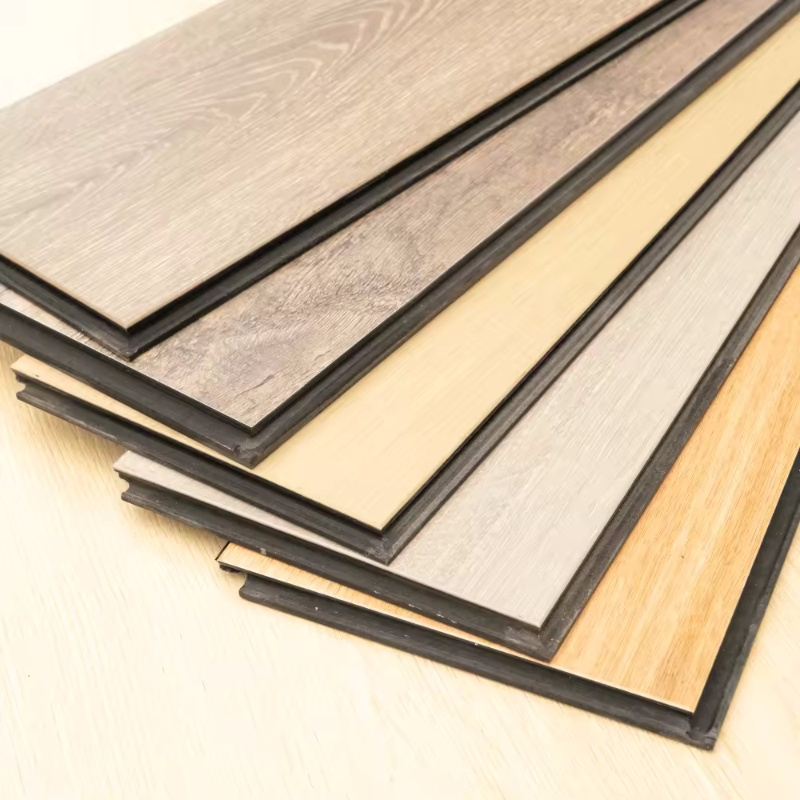

High gloss waterproof laminate flooring is a multi-layered synthetic flooring product designed to replicate the appearance of polished hardwood while offering excellent water resistance. Its key components include:

Wear Layer – A clear, ultra-glossy protective coating that resists scratches and stains.

Decorative Layer – A high-definition wood grain print that adds depth and realism.

Waterproof Core – Typically made of high-density fiberboard (HDF) with water-repelling properties.

Backing Layer – A moisture-resistant underlayer that stabilizes the floor and prevents warping.

The signature high-gloss finish gives high gloss waterproof laminate flooring a mirror-like shine, making rooms feel brighter and more spacious.

Advantages of High Gloss Waterproof Laminate Flooring

Elegant Appearance

The reflective surface of high gloss waterproof laminate flooring adds a luxurious touch to any interior. It enhances natural light and creates a clean, modern feel that complements both contemporary and classic designs.Waterproof Performance

With a sealed core and tight-locking edges, high gloss waterproof laminate flooring protects against spills, splashes, and humidity. It's an ideal solution for kitchens, bathrooms, laundry rooms, and basements.Scratch and Stain Resistance

The tough wear layer of high gloss waterproof laminate flooring resists scuffs, scratches, and common household stains, making it perfect for high-traffic areas and homes with kids or pets.Easy to Clean and Maintain

A smooth, glossy surface means dust, dirt, and liquid can be wiped away effortlessly. Unlike natural hardwood, high gloss waterproof laminate flooring doesn’t require waxing or refinishing.Fast Installation

Most high gloss waterproof laminate flooring features a click-lock system, allowing for quick, glue-free installation. It can be floated over existing subfloors without extensive preparation.

Ideal Applications for High Gloss Waterproof Laminate Flooring

Living Rooms and Dining Areas: Add sophistication and reflect light for a more spacious feel.

Kitchens and Bathrooms: With its moisture resistance, high gloss waterproof laminate flooring performs well in wet-prone areas.

Retail and Commercial Spaces: Impress clients and customers with a sleek, professional finish.

Entryways and Hallways: Make a bold first impression while withstanding foot traffic and moisture from outdoors.

Choosing the Best High Gloss Waterproof Laminate Flooring

When selecting high gloss waterproof laminate flooring, consider the following:

Gloss Level: Choose a shine level that suits your lighting and aesthetic—some high gloss finishes reflect more light than others.

Waterproof Duration: Look for water resistance ratings (e.g., 24hr, 72hr) that match your needs.

Plank Size and Design: Wider planks can create a modern look, while narrow boards provide a more classic appearance.

AC Rating: For homes, AC3 is usually sufficient; for commercial use, go for AC4 or higher.

Color and Pattern: From rich walnut to sleek white oak, high gloss waterproof laminate flooring comes in a wide variety of options to match any décor.

Maintenance Tips for High Gloss Waterproof Laminate Flooring

To keep your high gloss waterproof laminate flooring looking its best:

Use a microfiber mop or damp cloth to clean regularly.

Avoid abrasive tools or harsh cleaners that may dull the glossy surface.

Place mats at entrances to trap moisture and dirt.

Use felt pads under furniture to prevent scratches.

Conclusion

High gloss waterproof laminate flooring is a stylish, functional flooring solution that brings shine, resilience, and moisture protection into any space. Its modern appearance, easy upkeep, and resistance to daily wear make it a top choice for homes and businesses alike. Whether you want to add luxury to a living room or create a polished commercial space, high gloss waterproof laminate flooring delivers beauty and performance you can trust.

Submitted successfully

We will contact you as soon as possible